With the wrap all in place, heat and lights and fans installed inside, and all the deck hardware bagged and labeled, Ethan started taking off the decks. We knew this would be a labor intensive project, but it’s actually going really fast. There is no pretense that the teak can be saved or reused. It’s glued down hard and comes up in little bits.

This shows just how thin these decks were worn. This is on the starboard side between the cockpit and the gate. We lived aboard for 13 years and the original owners for probably about that same amount. Before we repowered and the direction of our prop changed, we always preferred a starboard docking to take advantage of the prop torque when stopping. This was probablly the area with the highest wear on the boat, and also the area where Rob had been repairing cracked boards.

We said goodbye to the two deck prisms, with mixed feelings. We love the light they bring, but hate the maintenance. Neither of us even considered adding them back in to the new fiberglass decks.

Ethan and Michael made good progress, getting about half way through the deck in less than two days. Michael stays ahead and pulls out the screws while Ethan has a power tool with a sharp blade that cuts the sealant between the boards and the cabin top.

This is the end of the first day, after working about 5 hours on the teak removal.

And this is what the teak looks like before it goes in the dumpster. It would have been nice to bring home some usable wood to Rob’s woodshop, but nope.

On Thursday Ethan took the day off so Michael got ahead of him removing screws.

Meanwhile I spent the week belowdecks removing the rest of the headliner. Ethan needs to remove all the hardware off the cabin top so he can grind down the nonskid there and make it match what he applies to the decks. Unfortunately the sheet guards we have around the dorades are through bolted and in every compartment. So I had to remove headliner from every cabin. The bolts above are the staysail track, and all those need to come off.

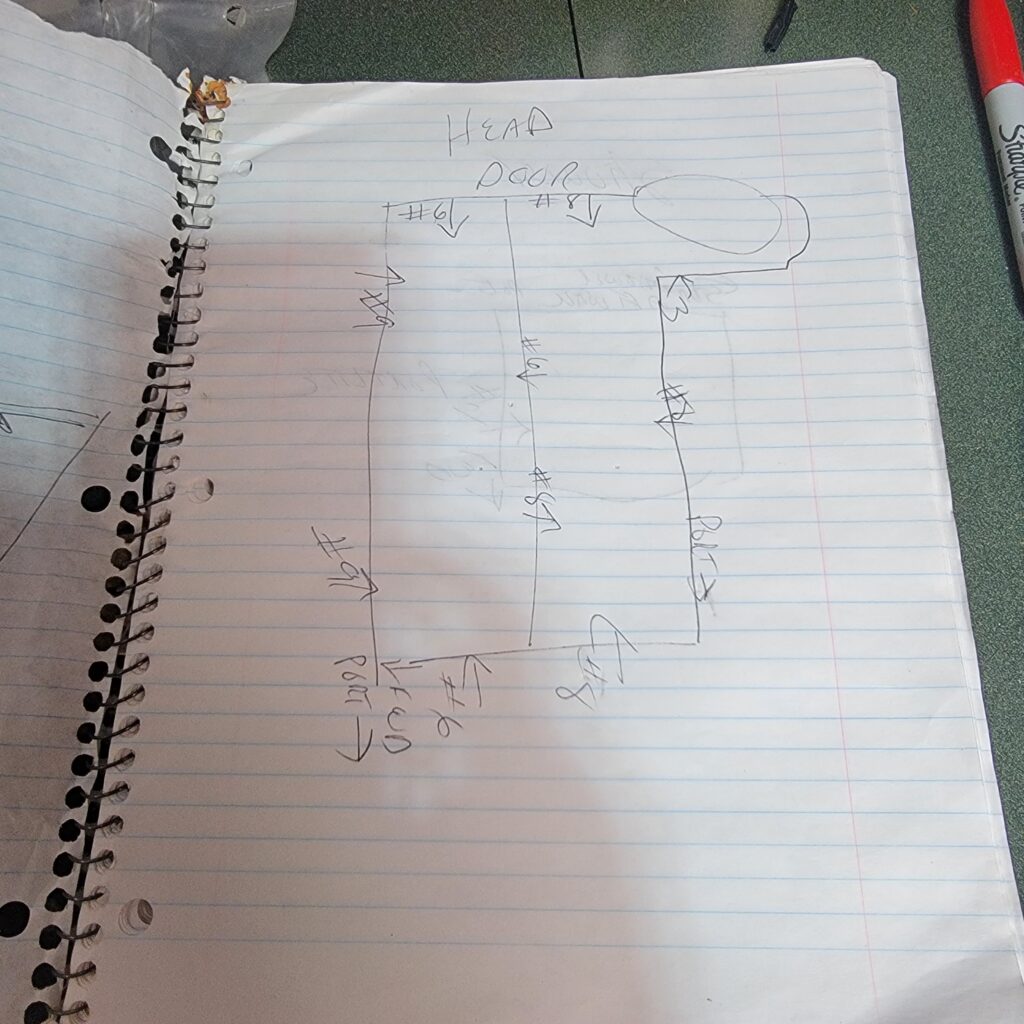

All the little tiny trim strips that hold up the veneer are marked with numbers and directions. But I still made a map so when we put them back together (after some varnish renewal), we’ll have a clue how the puzzle pices fit back in.

The forward cabin headliner is down and the removal of that prism means we need to replace that piece to cover that hole.

Right behind us in the boatyard was a shell of a boat that had been completely stripped. I was curious about who was paying the expensive lay day costs. It was not in the storage portion, it was in the working area. On Wednesday we found out what was going on. It was an abandoned boat that our state Department of Natural Resources was paying LaConner Maritime to scrap and send to the landfill. It was interesting but sad watching the heavy equipment make quick work of taking what was at one time someone’s dream boat, and filling the dumpster. It took about an hour and the spot was completely empty and the scraps were ready to go.