Ethan and Michael continued to rip through the deck removal at quite a good pace. The foreward end, though, was more of a challenge.

The toerail comes down to deck level at the front of the boat, and they had to work around and actually get underneath the toerail there. That piece of wood forward of the samson post was added by Rob in 2005 when we pulled off the bowsprit the first time. TaShing had left a gap up there, and Rob filled it in. That will come off and Ethan will fiberglass up to the bottom of the new bowsprit this time.

The work required precision cuts to keep from damaging the toerail.

The toerail was laid over decking which had to be removed from underneath it. There was no way anyone wanted anything to do with removing and reinstalling the toe rail, so they drilled and dug out the old teak.

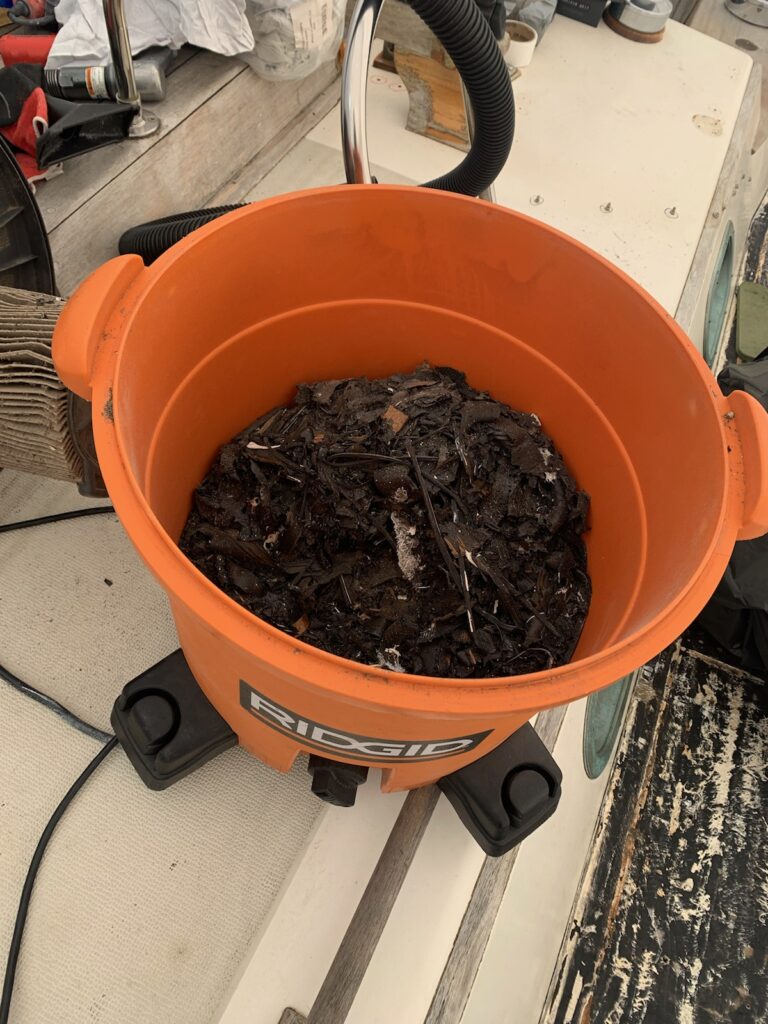

Underneath the decks was whatever black goo TaShing used to seal and hold the teak down. They now had to scrape that off to get to a surface they could grind down and make ready for fiberglass.

This is how much goo was on one side of the deck.

One challenge with our deck installation will be the scuppers. The teak decks were built right up to the bottom of the scupper, and now with the teak gone the water won’t drain out. We don’t want to build the entire deck system up just to meet the scuppers, so Ethan will lower the scuppers to meet the level of the new decks when the fiberglass is done.

On the outside of the hull there is a teak trim board beneath those scuppers, but Ethan is confident he can remove that ring around the scupper and lower the opening without disrupting that teak trim piece.

They also had to remove all of the hardware off the top of the house. That 40 year old nonskid will be ground off and a new finish that matches the decks will be applied. I’ve got to say I won’t miss scrubbing that old nonskid, it was getting reallly hard to keep clean.

With the decks scraped and the hardware gone, she’s looking like she’s almost ready for a new finish.

We aren’t doing any work in the cockpit, so Ethan laid ram board down to protect the exiisting wood there. He promises this fiberglass work is messy, and from the little I’ve seen I absolutely believe him.

Now with all the teak and goo gone, it was time for the moment of truth. What we did not know was how much water had gotten into the core, and how much rot there would be. We all expected at least a little bit of damage. Ethan has spent significant time (and $) on previous projects cutting into the deck and repairing rotten wood. Our deck is two thin sheets of fiberglass with an end grain balsa core layer between. The balsa is very susceptible to rot when it gets wet. Had water penetrated beneath the teak and first fiberglass layer? That’s what this meter was about to tell us.

And YAY, the answer was NO! The decks were dry all the way around. There are no soft spots that feel like rot that has dried, and no indication on the meter that there is any amount of moisture underneath worth cutting into the fiberbglass. This was our biggest concern and a significant wild card in the price of this project. It’s a happy day to see that meter read green all around the decks.