Now with the deck material gone it was time to clean and prep for fiberglass. Every job, no matter how big or small, lives and dies by how well the prep work is done. Ethan knows all too well that this is a critical time to ensure the quality of the final finish. So first it’s time to grind. Grind off the rest of the sealant that was under the teak, and grind down the old nonskid on the cabin top. What we didn’t expect was a bit of a circus to find the grinding disks he needed. He knew the poor quality ones from Harbor Freight were just too fragile for this task. He finally found what he needed and made a run up to Bellingham to buy them. And us? Well we were packing and off for a trip to South American that had been planned long, long before this work was scheduled.

So the grinding began, cleaning and fairing the surface and the cabin top.

We’re told this is particularly nasty work, and we absolutely believe that. We had ordered in all the safety gear from Fisheries Supply, and Ethan made sure he and Michael were well protected.

Another part of the prep was taking off the trim rings around the portlights. We had resealed those last in our 2005 refit, and it was time for a cleanup and new sealant. Plus, as a big bonus, the sides of the cabin top will get new gelcoat during this process. The current 40 year old gelcoat is wearing thin in so many places. I’ll get the bronze rings into some vinegar and add a little bling to the outside when it’s done.

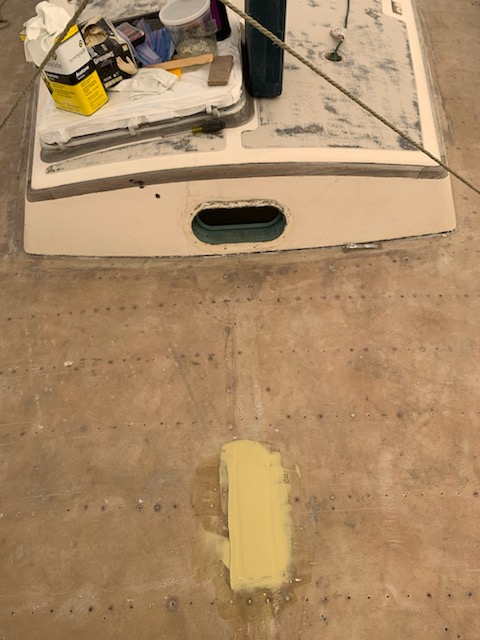

Another big task is to fill in two holes in the deck where the deck prisms previously resided. This requires not only work above decks, but also new headliners below decks (more on that later).

Coosa board (a lightweight composite fiberglass board) is used to fill the two holes.

And there it is, just a former prism now part of the foredeck.

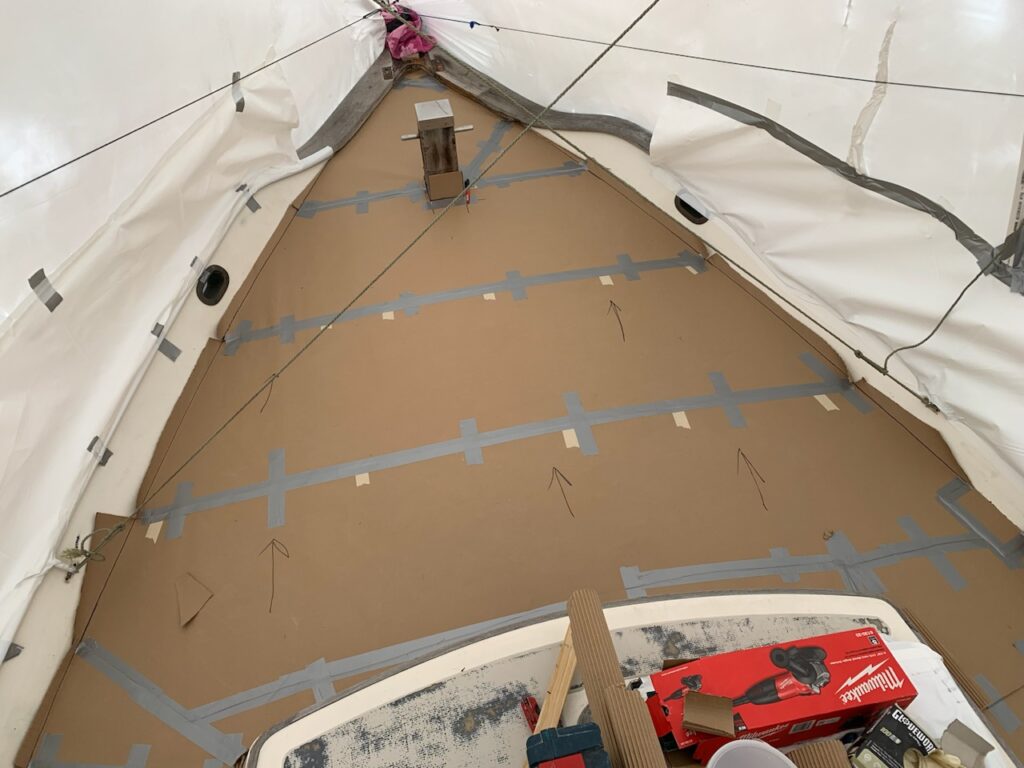

Next is time to pattern the decks for fiberglass cloth.

As we have seen all along, precision at every step. These patterns will soon become fiberglass.

They build a little table on the top of the house to roll out the cloth from the patterns.

And here’s where we end this week. I’m grateful that Ethan is sending me pix and info all through this process. It’s unusual for us to not be there helping out, but this is really their job to do and I’m so happy to see it progressing so well.