While we toured around South America (including walking on Cape Horn!), Ethan and Michael continued the hard work on the decks. Above is a pic of what he described as his “arsenal of longboards and blocks”. He continued to send me snippets and pix, and I’ll try and get those into these next posts in a way that makes sense. I’m sorry we weren’t closer and keeping up with the progress, but our trip dates couldn’t be changed. Ethan did the best he could to keep us updated even though our bandwidth was less than stellar at times.

When we left off last time they had patterned and were cutting the fiberglass sheets.

In addition to the fiberglass they also cut some peel ply.

What is that? To google for an answer: “Peel ply is a fabric layer placed over a composite laminate during curing that leaves a textured surface when removed. It saves time by reducing or eliminating the need for sanding, provides a surface ideal for secondary bonding, and holds excess resin, volatiles, and air. It’s a common material in industries like aerospace, automotive, and marine engineering where high-quality finishes are important.”

How it’s used

- Apply fiberglass and resin as you normally would.

- Lay the peel ply smoothly over the wet laminate.

- Use a plastic spreader to ensure good contact and remove air bubbles.

- Allow the composite to cure completely.

- Peel off the peel ply, ideally at a sharp angle, to reveal the finished surface.

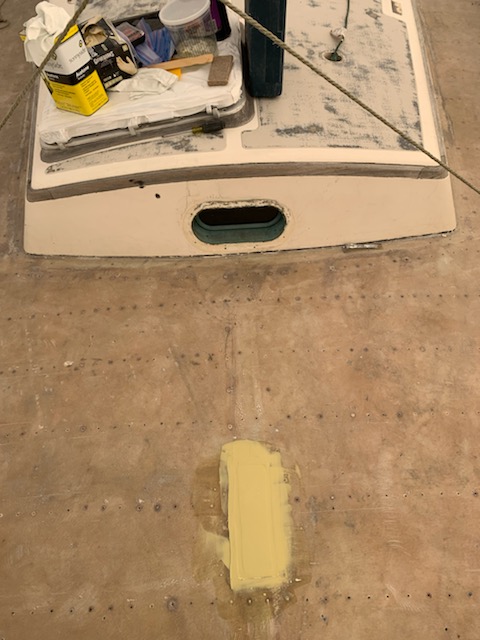

First they lay a coat of resin followed by fiberfiller to fill all the holes.

Then two piles of 1.5 ounce matt and a peel ply while the fiberfiller is still wet. They do staggered butt joints to reduce fairing.

Port side deck glassed, bye bye leaky deck prism.

And the foredeck glassed and second prism gone.

Next they laid fairing compound on the decks. Google tells me: “Fairing compound is a putty-like substance used to fill and smooth surfaces, making them level and even. It consists of a resin mixed with fillers, giving it a peanut-butter-like consistency that is easy to apply and doesn’t sag on vertical surfaces. It is used for cosmetic repairs, structural fixes, and can be used on various materials, particularly in boat building, where it’s common for both above and below waterline applications.”

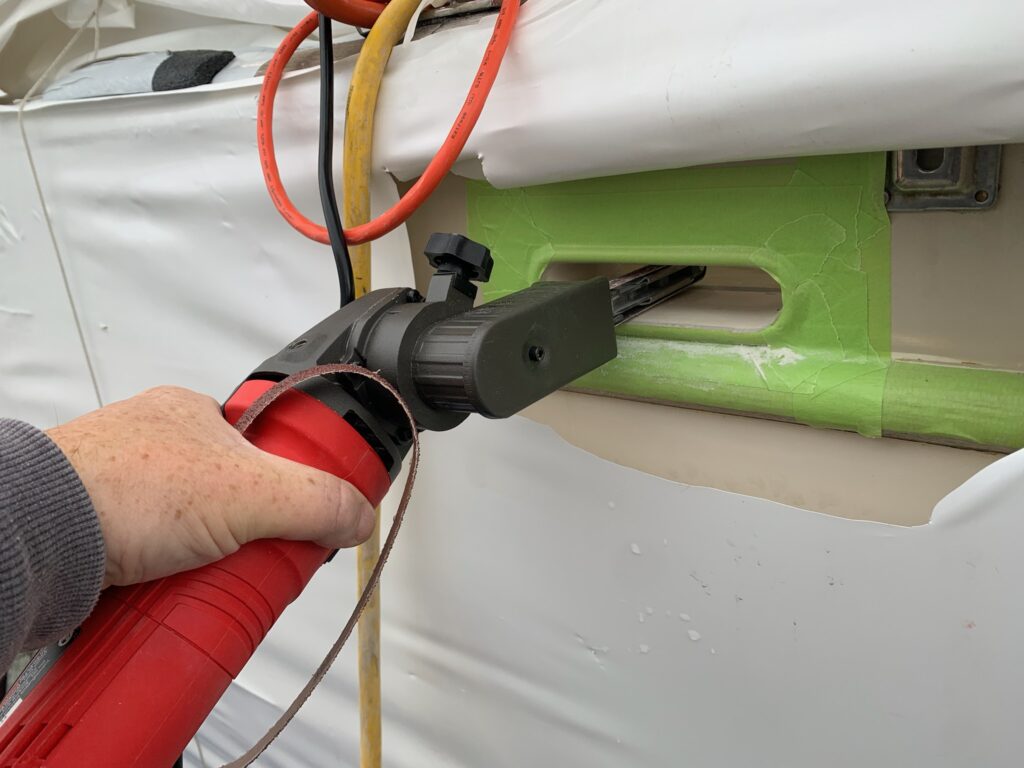

Since the purpose of fairing is to create a smooth surface, lots of sanding is involved during this process.

This is the foredeck and side decks after being faired.

Then it’s time for the fillet, which Ethan does with a master wax fillet ball. What is a fillet? It’s the rounding of an interior or exterior corner.

Now it’s time to cut the scuppers down to the level of the new deck. I would be terrified to make this first cut, but Ethan knows how these boats are built and where and how he can hack into them.

And here we are with the fillets, scuppers and decks faired.