Goal #1 with Yohelah is to make her easier to sail. First on the list, and easiest to accomplish is getting rid of the sail cover. It’s big and heavy and too high up for me to easily reach. Going out for a day sail means taking it down, stowing it away below, then reinstalling. The answer is a stack pack, which is a is a modern type of sail cover. It is secured to the boom and zips closed at the top to protect the sail from sun damage when it’s not in use. No more taking down the sail cover, it just stays attached to the boom.

Sailrite is the company that I buy sewing supplies from, and they have a video with instructions to build your own, and a parts list of all the things I’ll need. First on the agenda was to make a prototype of the forward end to be sure that the 60″ width of the sunbrella was enough to zip up over the top of the headboard on the main sail.

Then it was time to order the fabric and make that first scary cut. I was happy to find that Seattle Fabrics would drop ship me the sunbrella from their supplier for $10/yard less than Sailrite, so that saved a lot of money. Our boom is 16′ long, so that’s at least 5 yards of fabric.

This is a sign in Rob’s wood shop. Making the first cut on all that fabric truly was scary.

I used Rob’s laser level to create the 15 foot line down the length of the fabric.

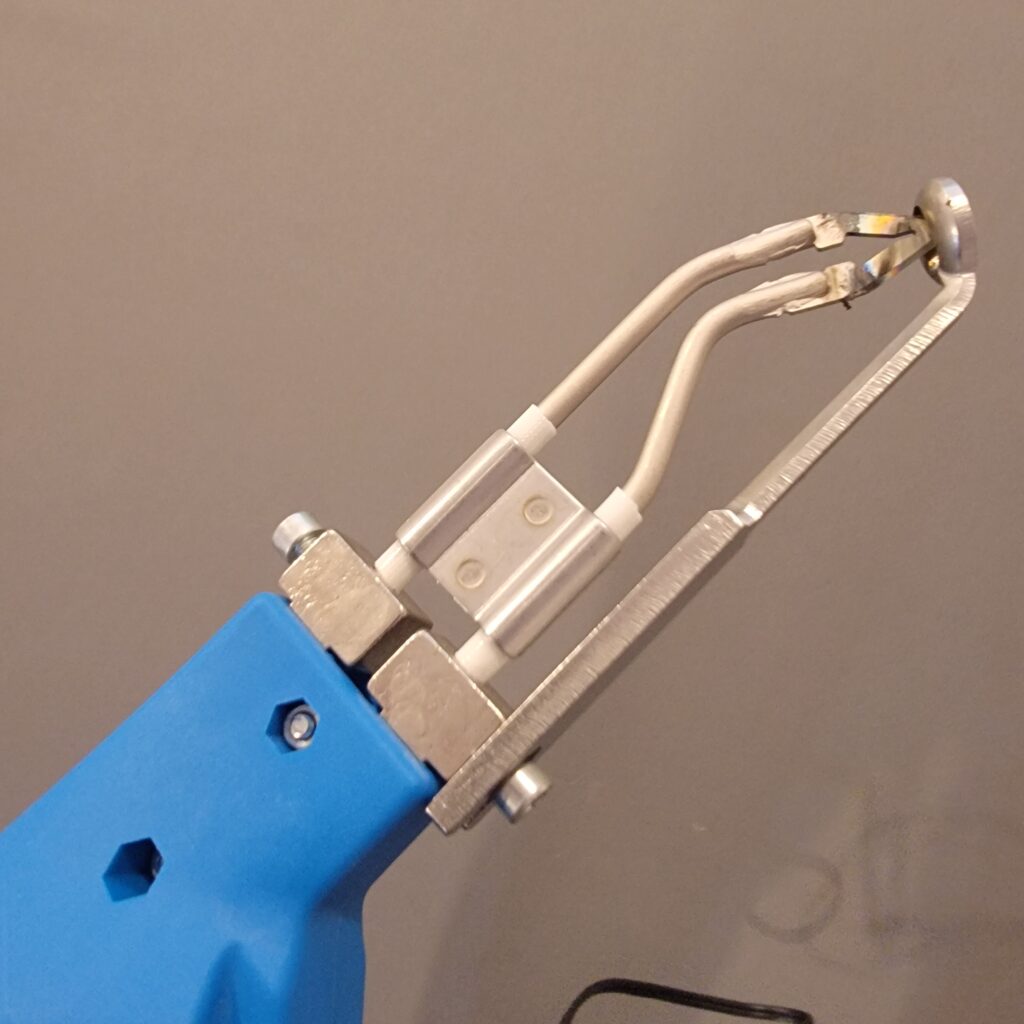

And took the opportunity to buy a nice new blade for my hotknife. This way I can cut anywhere without damage to the surface below. I’m still not very good at cutting a straight line, but you can’t tell with all the seams finished on the final product.

After measuring twic, I cut once and it seems to be right.

Here is the mostly finished product with the zipper on top and channels for some pvc pipe to give it structure on top. The bottom has fasteners which secure beneath the sail.

Once the cover was built I had to do a bunch of triangle math to figure out how much line to buy and how long to make each leg of the lazy jacks. This is how the stackpack is supported, and what controls the sail as it’s dropped back into the bag. We already have lazy jacks on the boat but they’re 25 years old and past due to be replaced. What I knew was that the block on the spreaders was 22.5 feet above the top of the stack pack and there were four attachment points. Then it was a bunch of math to calculate how much line to buy and how long each leg would be.

With the line ordered and tied onto the new stack pack it was time for a fit test. I needed measurements around the front of the boom to make the last bit that goes around the front of the mast and attaches on both sides to the new bag.

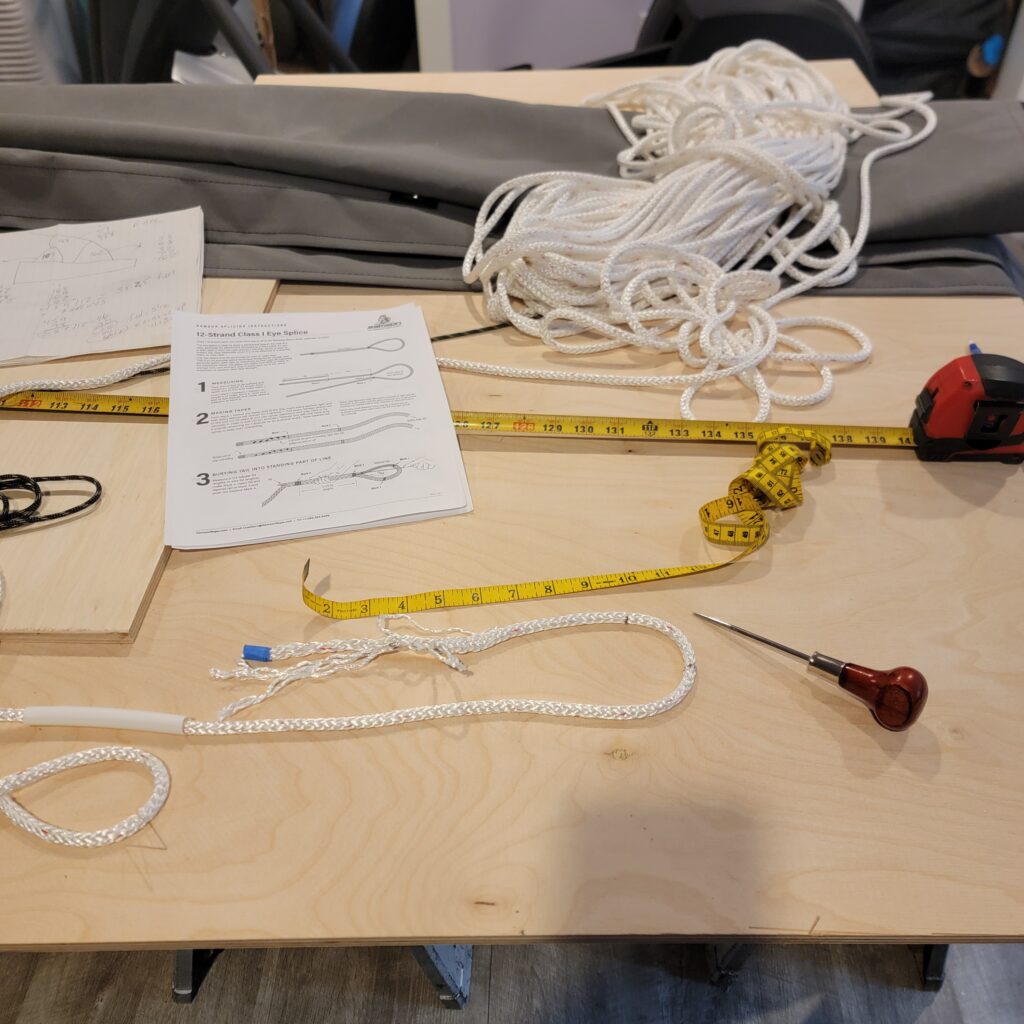

In the video instructions and on other stack packs we saw in the marina, the lines were secured to the pack with knots and used blocks overhead. I decided it was time to dust off the splicing wand and get the instructions out for a 12 strand single braid eye splice. It is actually a very easy splice, thankfully, since I needed to make fourteen of them.

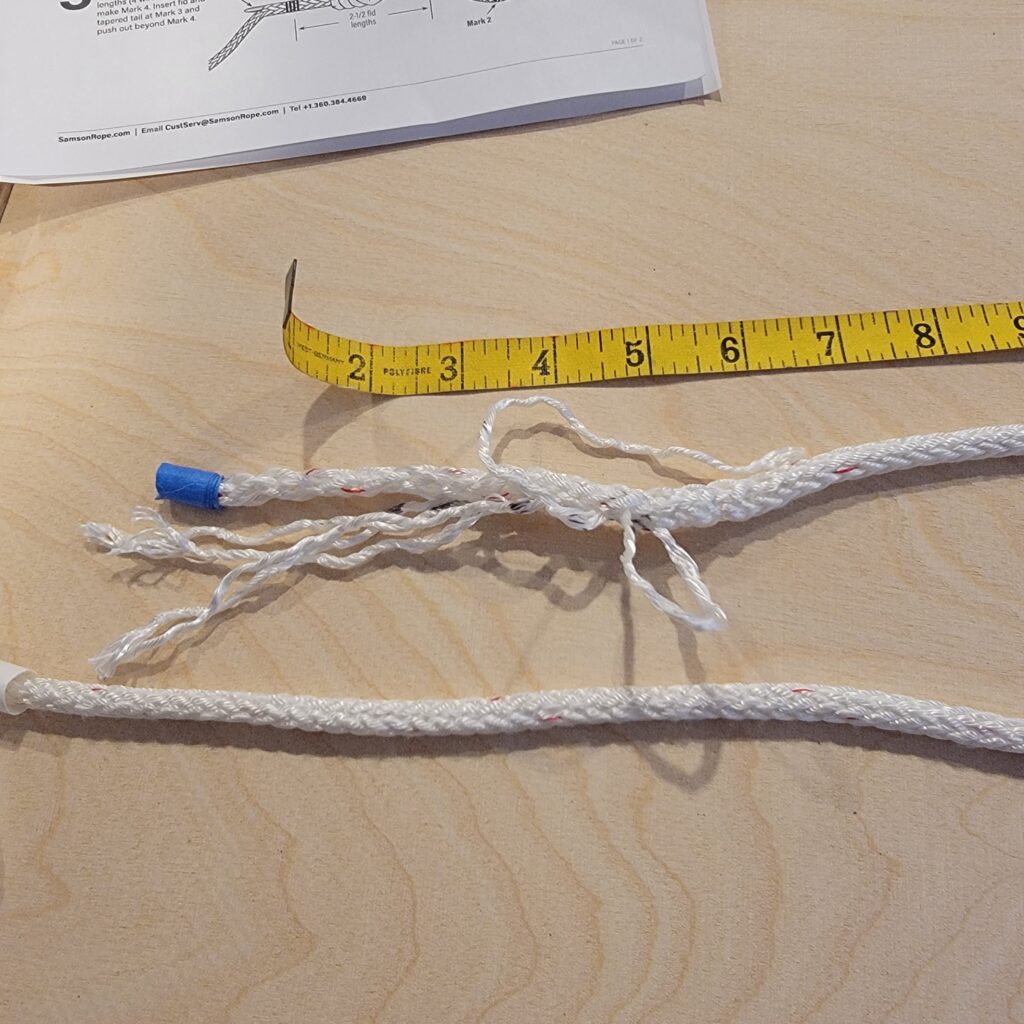

To make the splice you make four different marks on the line, pull out half of the threads at different lengths to make a taper at the end, then push the wand in the hollow of the line and pull the end into the core.

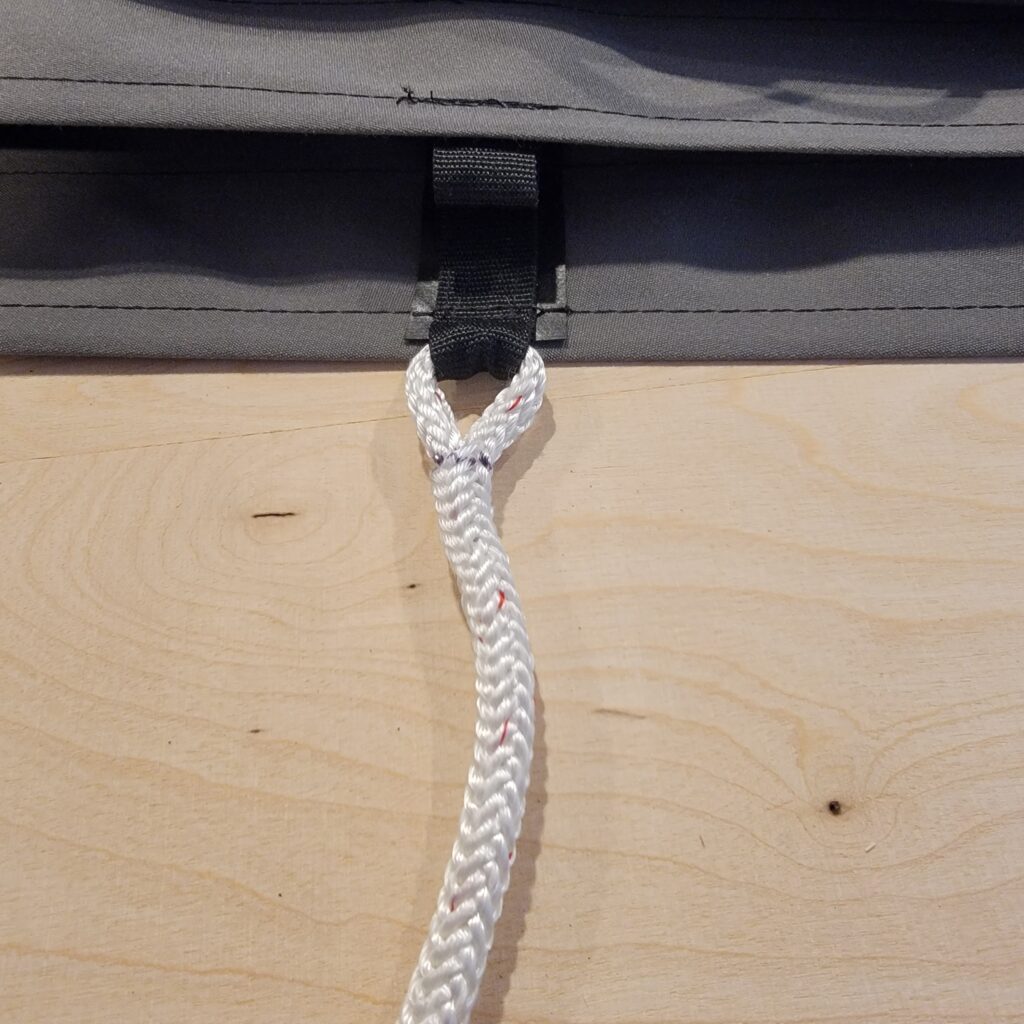

This is a finished splice, with the line secured to the top of the stack pack. In retrospect, what I realize now is that when the stackpack comes down for cleaning it’ll be tough to just toss it in the washer with all the lines spliced to it. Will have to think about that.

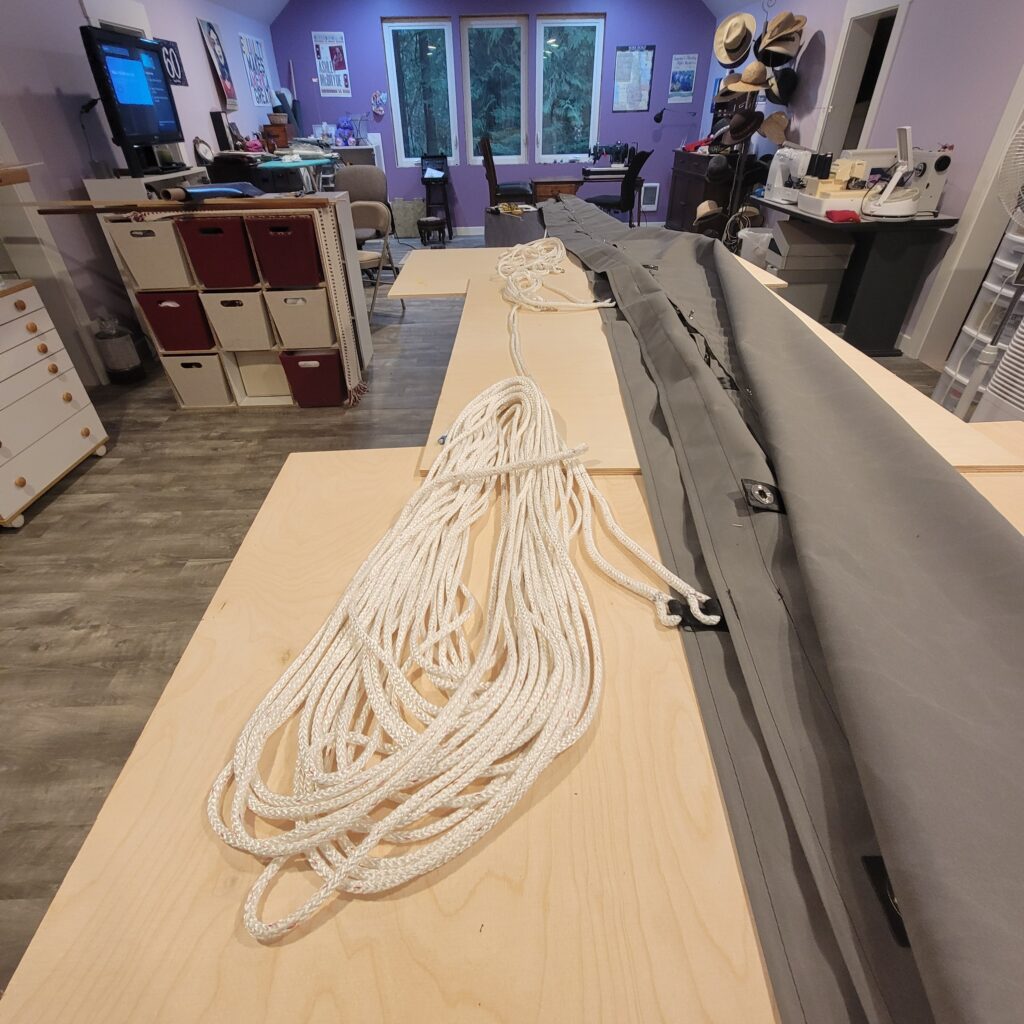

And all of the splices done. There are two long lines that will go up to the spreader and down to a cleat on the mast. Leaving these long will allow us to pull the lazy jacks up to the mast if needed to make hoisting the sail easier.

And there is the final stackpack. We need to get out and hoist the sail and let her drop back in a little more evenly, but of course the day we fitted the new canvas, the wind piped up way too high to hoist at the dock. And I had other items on the agenda that day that kept us at the dock.

The first of those items was pulling down all the running rigging and taking it home for a bath.

Literally, an overnight soak in the tub, then into the washer the next day.

Also there were two pieces of canvas that came home for a cleaning and ended up being replaced. The first is the mast boot cover. It just wouldn’t come clean in the wash, so in a couple of hours I had a new one ready to install.

The other was the custom cover for the lifesling. The original was probably 10 years old and well into time to replace. That took up a whole day to replicate again, but it’s now new and spiffy clean.

I’m working on the exterior and interior teak, plus taking the tarnish off the portlights and repainting in between. Will post some pix when all of that is done. For now, I’m just super happy to have some time to mess about on the boat. Spring has been absolutely gorgeous here, and I’m grateful for every day I get to spend at the marina making Yohelah beautiful once again and easier to sail.