Here is the best picture we have of the teak decks after our overhaul in 2005. With no cell phone camera in hand at that time, we did not record the pix of finishing the deck overhaul. At that point the decks were 20 years old, and the boat had been lived on most of her life. We spent 4 weeks with both of us working full time to strip the caulk between all the boards and reseal them, plus drill out and replace all the worn bungs and reseal every piece of hardware that penetrated the decks before we went offshore.

This is what it looked like when the boat was in the shed during our refit, and the decks were ready to recaulk. Rob wrote up the process for our website, long before we had our blog. That article is here: Deck Caulking.

Part of deck maintenance is replacing the bungs. The decks are glued down, and also screwed down. Every place a screw exists, a hole is counter sunk into the teak, and a wood bung is glued in over the screw. Then the bung is sanded flush with the decks. It’s easy to see above there are lots of bungs. And over time as the teak wears down, the bungs are worn, and they break and fall out. Then the process must be repeated – drill out any remaining parts of the bung, scrape the remaining epoxy off the screw head, remove the screw, counter sink a hole a little deeper, add another screw, epoxy, bung and sand.

The old adage that “Cruising means working on your boat in foreign ports” is absolutely 1000% true. The decks took a lot of wear while we were offshore. Here I am in Ecuador, drilling deck bungs. We’re home now, but the decks continue to get used and the boards wear thinner and thinner every year.

Besides worn out bungs, the deck boards are now beginning to crack and require replacement. We don’t know, with the deck glued down, exactly how much water encroachment we have into the cabin top when a board cracks, but we don’t want to take a chance of destroying the underlying structure beneath the boards.

In addition to boards, we have other items that penetrate the decks and have sealant that fails with age and use. There are two deck prisms in Yohelah, which disperse light down into what could be an otherwise dark space. We have two huge overhead hatches in the main salon, and the deck prisms have become more maintenance than they’re worth. When the sealant fails, it doesn’t completely fail, just starts leaking. So again, Rob has to pry up the glass without chipping the ediges of the prism.

He has to pry up each broken board, make a wax prototype to verify the shape, then he goes into his shop and replicates the boards. Of course teak is very expensive, and none of these boards are straight, so each board has to be shaped to the curve of the deck. Also, when the sealant between the boards gets too thin it loses adhesion and we have to dig down deeper into the gap and reseal.

This is a repair he made last fall. The prism was leaking, boards were cracked, the jib track was leaking. The boat was basically a swamp below in the Pacific NW rainy winter, and we spent a lot of time trying to get her to stay dry.

After we started sailing this spring, the decks gave us a very clear message that it was just time. This is only a small piece of the side deck, but the entire boat pretty much looks like this now. The good news is that we already knew, and have the logistics and workers in place to get this work done this winter.

Two of our pals in our Bainbridge sailing tribe have a Passport 40, which is of the same vintage as Yohelah. They also had failing teak decks and found “the guy” last year who would replace them. We called up Ethan and made an appointment for him to come to Eagle Harbor and have a look at our upcoming project. He gave us absolute confidence that this job will be done right, so we signed up for his services starting in September. This is Rounder above, and we have all the confidence that Yohelah will look just as good when she comes back home.

On the discussion group for Baba/Panda/Tashiba sailboats this year I’ve been watching with much interest as a boat named Mandolin documented the process of removing their teak decks. I’m pretty sure we met Mandolin in the Marquesas in 2009, when they were doing a quick 1 or 2 year Pacific loop after they bought the boat. They live in Southern California and took the boat to Ensanada for this project, where the labor rate was significantly less than what we’ll pay in the Pacific NW. There were some substantial logistical challenges, since they didn’t haul out and had to do the work at the dock. That meant actually motoring out into the bay and anchoring when the sanding and dust was too much for the neighbors. I’ll save my commentary about environmental concerns and protections in Ensanada. In the end, though, their decks turned out looking really nice.

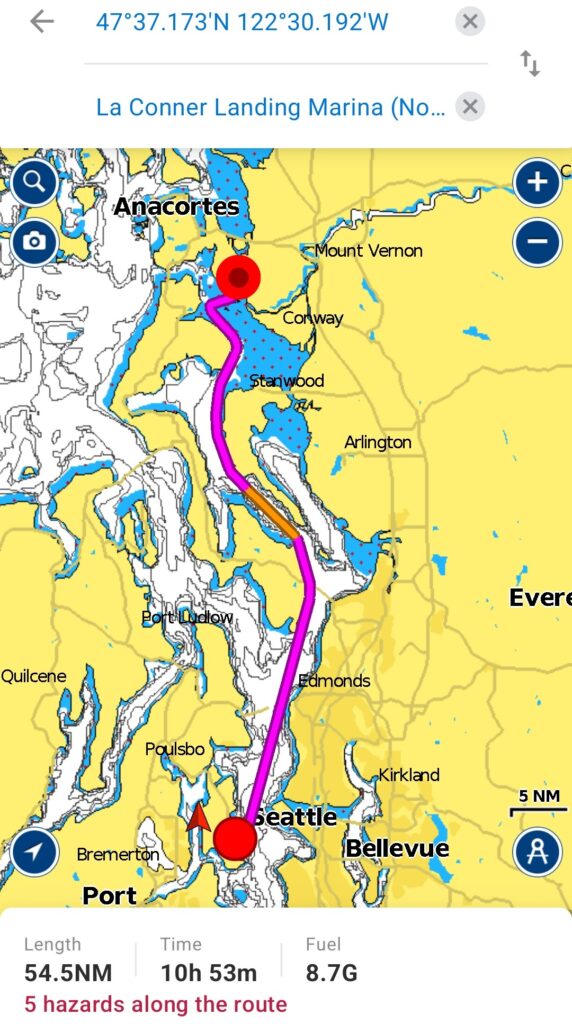

Ethan lives in Anacortes, a lovely small town on a peninsula 90 miles north of us. It’s the gateway to the San Juan Islands, where we kept our boat in a marina one year and have visited many times. Unfortunately the boat yard Ethan worked at last year didn’t work out for this year, so he found space in LaConner, which is in the Skagit Valley just south of Anacortes. Today we took Nonnie’s Diner (our Outdoors RV) to an RV park nearby to live in while we help work on the boat.

We’ll pack up the cats and leave tomorrow morning early. Of course we have a very strong flood starting at 6am, so the tide will be against us until we get to the entrance to Saratoga Passage. We’ll go into Coupeville and anchor there for the night tomorrow.

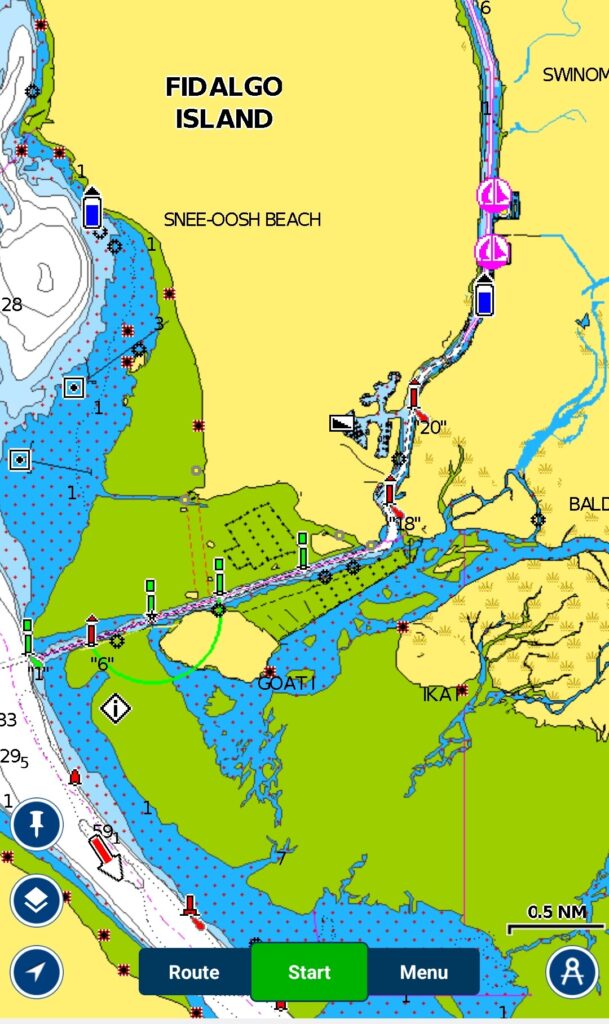

Then on Tuesday morning we’ll be very happy we have that same flood tide, as we need to transit the Swinomish Channel. The entrance has 4′ of water at low tide, and we draw 6′. It’s a very skinny channel that we’ve managed to avoid for 25 years. But the trip outside and around would mean going up around Anacortes and adding another 20 miles to the trip. Then we would still have to come south in the Swinomish Channel, so there’s no win there either.

So why? Why are we doing this? This is work that will take months, and may cost up to half the current resale value of the boat. We’ll know more about the cost when the old decks come off and we discover how much (if any) rot there is below. Why incur the time and expense? So many people our age decide that sailing is too much work, and choose to “go to the dark side”, meaning they sell the sailboat and buy a power boat.

We had six very good friends out last weekend for the best sail we’ve had in years. We left Eagle Harbor and circumnavigated Blake Island. When we have friends aboard we always share the helm and share the fun of feeling Yohelah move through the water purely by the power of the wind. Last weekend, I couldn’t let go. It was my day to sail, and I could not have been happier. I always say that when I’m sailing, it’s the place where my soul is at peace. That’s why we’ll do this refit, and keep trying to make her easier to sail and easier to maintain. I can’t imagine life without her.