Finally it was time to start spraying gelcoat. We had a choice between painting the topsides and spraying gelcoat. Paint is easier to apply, less expensive and easier to repair, but gelcoat lasts longer and provides better protection. Paint would need to be reapplied in 5-10 years. The current gelcoat is 40 years old, and I expect this new layer to last just as long. Although I do have to admit I may not still be sailing at 105 years old.

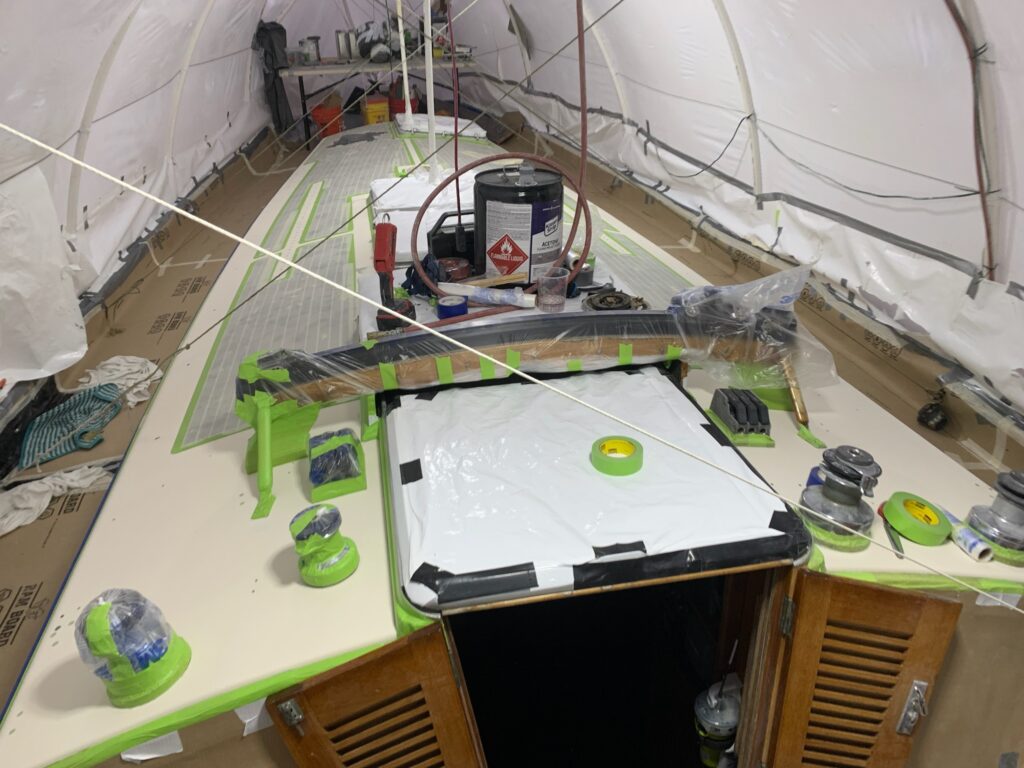

The cabin top was sprayed first, after laying ramboard on the decks to protect them. And as always it is safety first with plenty of protective gear for this crew. The old nonskid on the cabin top has been sanded and faired, and will get new non skid to match what is being applied to the decks after the gelcoat.

Some holes remain on the cabin top to reinstall hardware and the hard dodger.

They took a couple of days off to let the gelcoat set, then laid ramboard on the top so they could spray the sides and deck.

Ethan said this first coat was epic. I don’t know what that means in respect to spraying gelcoat, but I’ll just believe him of course. It looks great to me. Each section got three coats of gel, with the last coat containing a surface seal.

This is what he called his Rube Goldberg contraption which uses two compressors and two reserve tanks to give them enough air for this shoot. One of the many good things about this team, they own the right tools for the task.

Although he did buy a new pressure pot rig, but when is it not fun to get new equipment.

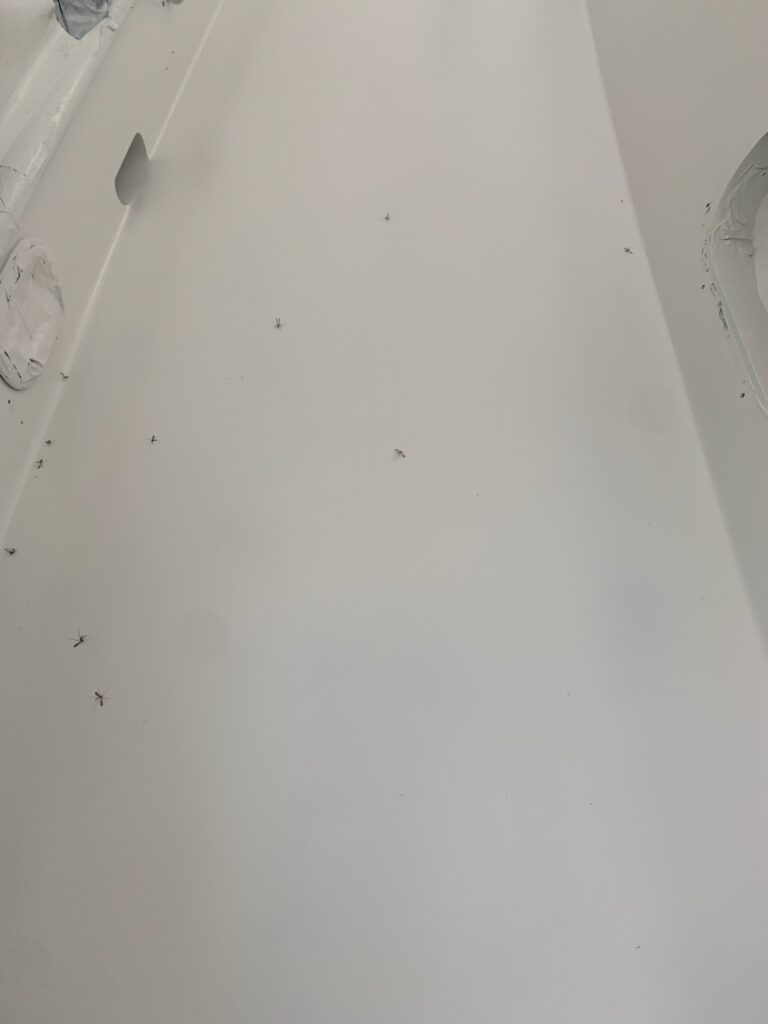

They took off early during Thanksgiving week, but worked on the actual holiday. I knew they were working and felt a little bad about enjoying my family time, but they had time off later in the week. I suspect Ethan’s wife was working on the holiday, so he chose to also. And who else showed up but a big swarm of bugs. My heart sank when he sent this pic, knowing full well what a pain it is to pick bugs out of paint. He said they did just wipe off, but they were slowing down the process (little buggers).

Again it’s time to add a guide coat, this time on top of the gelcoat.

They wetsand from 400 to 600 to 800 grit, then polish with Polarshine twice, with guide coat between all grits.

This is what Ethan called our teaser pic. It’s not waxed and there is one more mini detail polishing to be done, but I’d say it’s looking pretty darn good to me! This is going to be so much easier to keep clean.

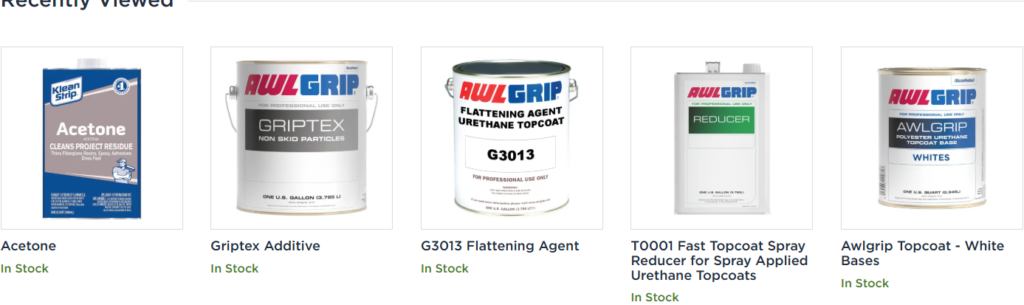

This week Ethan finally sent his last parts list, this one for the non skid. It’s been a great way to manage costs on this project – he looks at Fisheries Supply and sends me links. I call sales and buy them on an account that a friend lets me use to get a very deep discount, then LaConner Maritime is kind enough to let me put the parts on the Fisheries delivery truck so we don’t have to pay frieght. Normally the boat yards won’t let you do that because they want you to buy parts from them and pay their markup, but these folks have been very accomodating.

In January we’ll return to LaConner and start putting Yohelah back together again. The boat is in the yard at LaConner Maritime at the top of this map. Just south is the LaConner Marina RV Resort, which is owned by Skagit County. We’ll put the trailer in there for a couple of months now that they’re on winter monthly rates. Then we’re walking distance to the boat and town. Next posting I’ll send some pix of the final shine on the gelcoat. Tomorrow we go up to get the bowsprit and samson post so Rob can start working on replacing those in his shop. I can’t wait to see how she’s looking now.