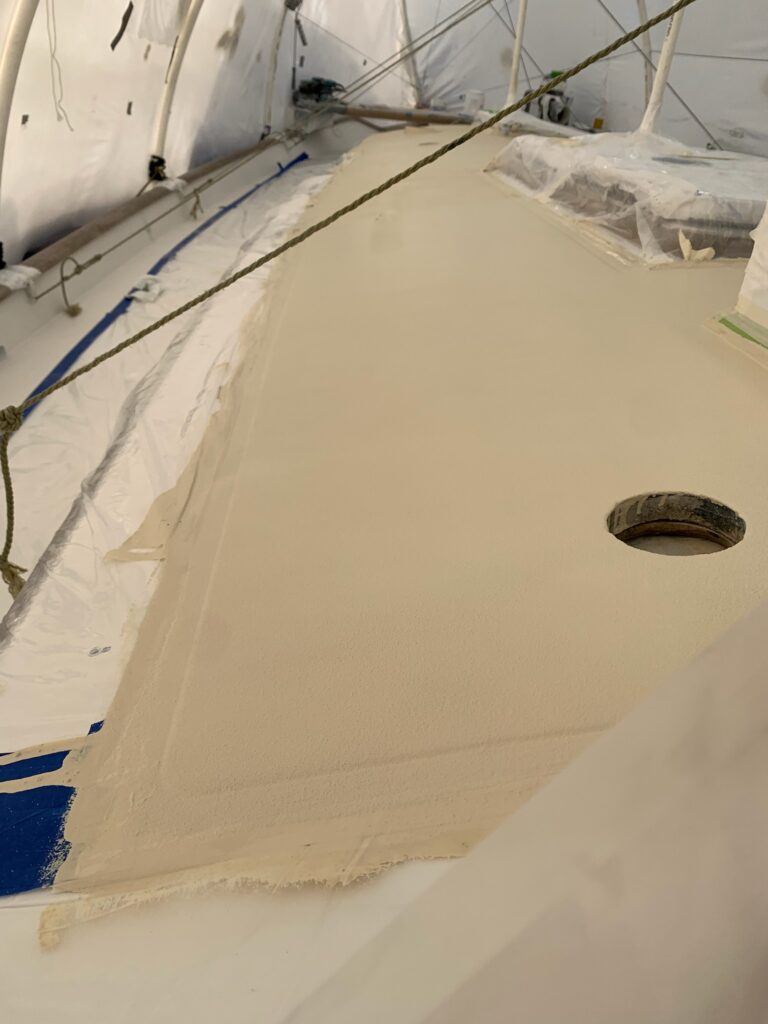

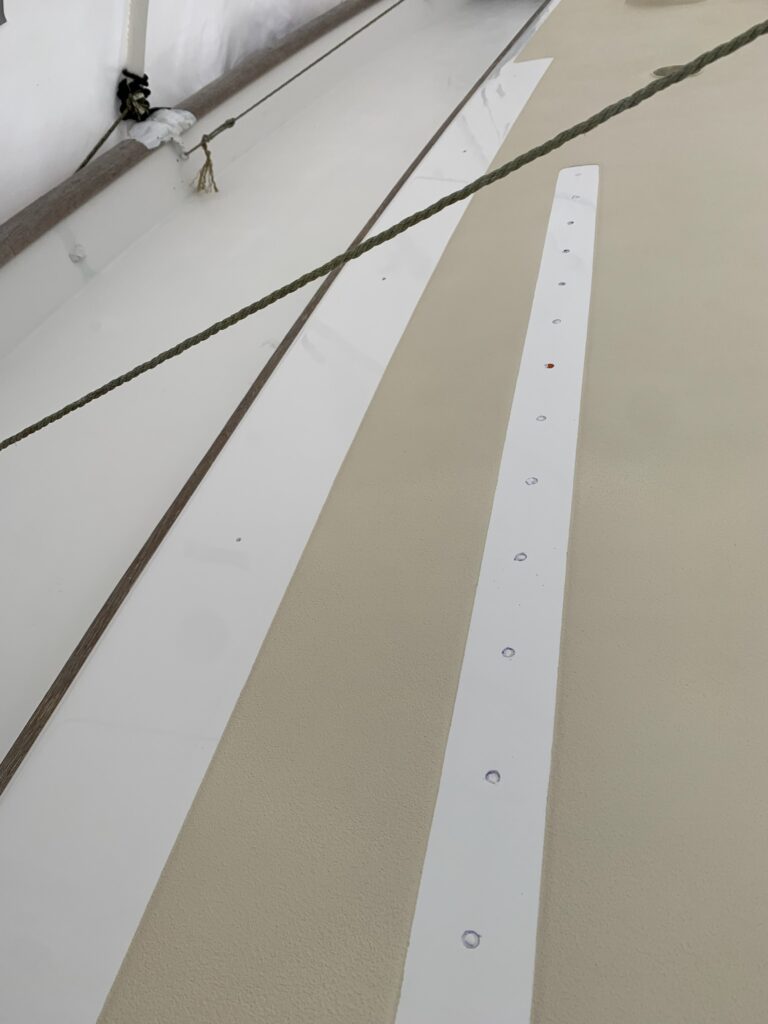

Here’s a sneak peek at what the cabin top looks like, post nonskid. It has taken a while to get to this point, but we have no complaints about the timing, quality of work, or results. The team has been working at their pace and we’re not in a big hurry. Some of this takes time to cure, holidays and family events happen, that’s just all ok. We’re busy in the shop at home, and will head back up to LaConner in another two weeks.

When we left off at week 14 they were sanding gelcoat. Here is how that looks, getting closer to final polishing.

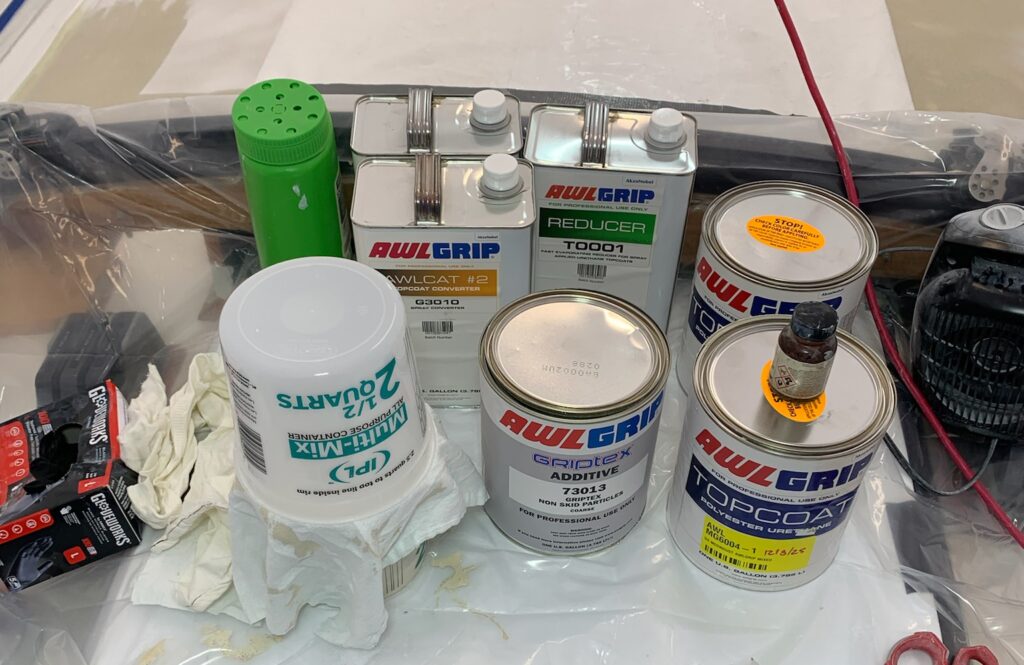

Then it was time for another (hopefully last) big order from Fisheries. Again, I’m grateful to Fisheries and LaConner Maritime for letting me buy and ship on the delivery truck right to the yard.

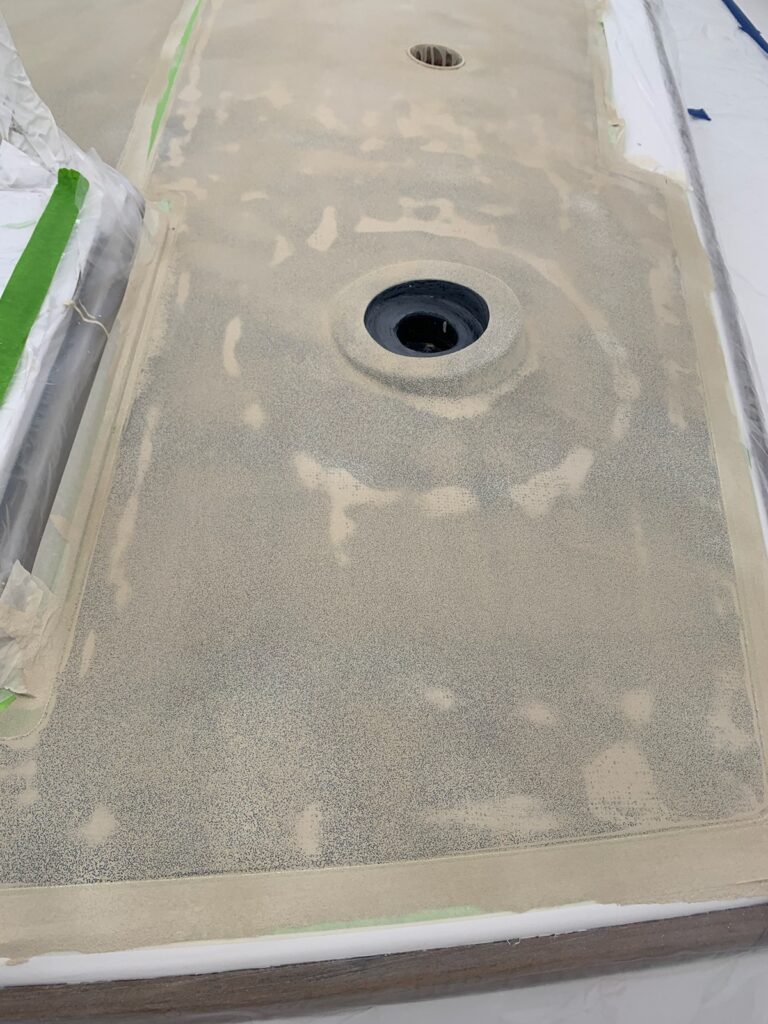

All the surrounding surfaces were taped and protected. The precision and detail here is so far beyond what I would ever have the skill or patience to accomplish.

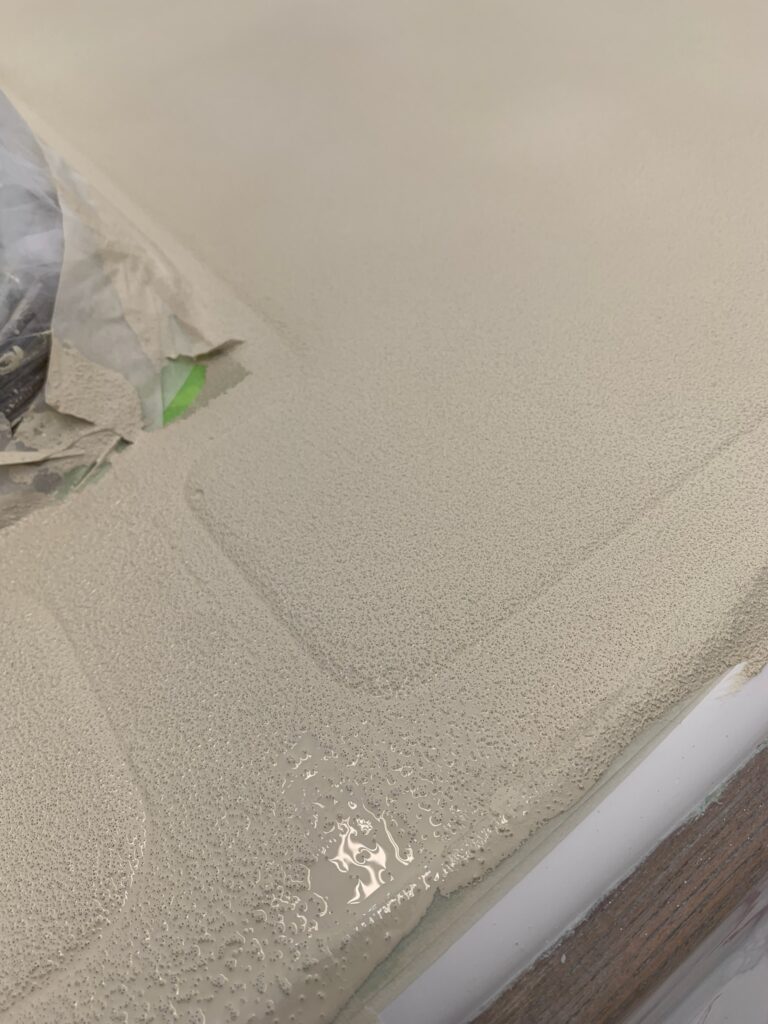

If you look at this first pic before realizing the work that has gone into prep and taping, it’s a little frightening.

We discussed the options for amount of grit in the nonskid. Awlgrip has three different levels of “grippiness”, we chose mid range “coarse”. We’re not going offshore in heavy seas again, but honestly this gelcoat is so slippery now, we thought a little more than “fine” was necessary. We also chose a color that we were happy with. The colors are custom mixed by Fisheries and part of the ordering process.

Four coats of Awlgrip go onto the cabin top.

The final coat has a flattening agent to reduce the gloss to a flat or semi gloss finish (this from google, I had no idea why).

This nonskid is going to be so much easier to clean up than the original. I have spent hours of my life scrubbing Pacific NW green from that original Taiwanese nonskid.

Once the fourth coat is on they pull the tape and then it cures for about 4 days. They timed this to get Christmas week mostly off.

The holes for the staysail jib track and handrail are marked and ready for a newly cleaned up track and brand new handrails.

Which is what we have been working on at home in Rob’s woodshop. All the hardware and tracks came home. Of course it was all covered in schmoo (sealant) and required hours of cleanup. A wire wheel takes off the sealant from the bases and bolts, and massive amounts of Flitz metal polish and scrubbing has everything looking shiny and new. It’s all marked with identifying location for reinstallation. Where bolts or screws were missing, a trip to Tacoma Screw got us everything we needed. Some of the hardware was just too ugly to put back on those shiny new decks, so I bought new deck fills for water, sewage and diesel, and also new deck pipes for the chain.

Rob has been working on disassembly of the bowsprit to figure out how to make a new one. Bob Perry didn’t have plans, so he’s reverse engineering. It helps to be pals with a Naval Architecht that we’ve known for decades – Garth came and talked with Rob from an experienced engineering standpoint about the sprit.

Off we went to our favorite hardwood dealer, Edensaw Woods in Port Townsend. Rob had settled on using sapele, which is an African hardwood. He has since planed these down and said the wood is just gorgeous. He will write a blog post when he’s done about the whole process. We also bought a 13′ board of teak from Edensaw to replace the handrails on the top deck. There will be more about that as he progresses on that piece of the project. Today I’ll finish cleaning sealant off the back of the portlight trim rings and hope I never have to use that wire wheel ever again.

Ethan and Michael are finishing the wet sanding and polishing of the gelcoat. Where on the top deck there were a couple of things to tape around for nonskid, the lower decks are much more complicated. All the deck hardware is dry fit and the area around each piece is taped off so there is no nonskid underneath anything. It’s a labor intensive process, but will be worth the work effort when it’s done.